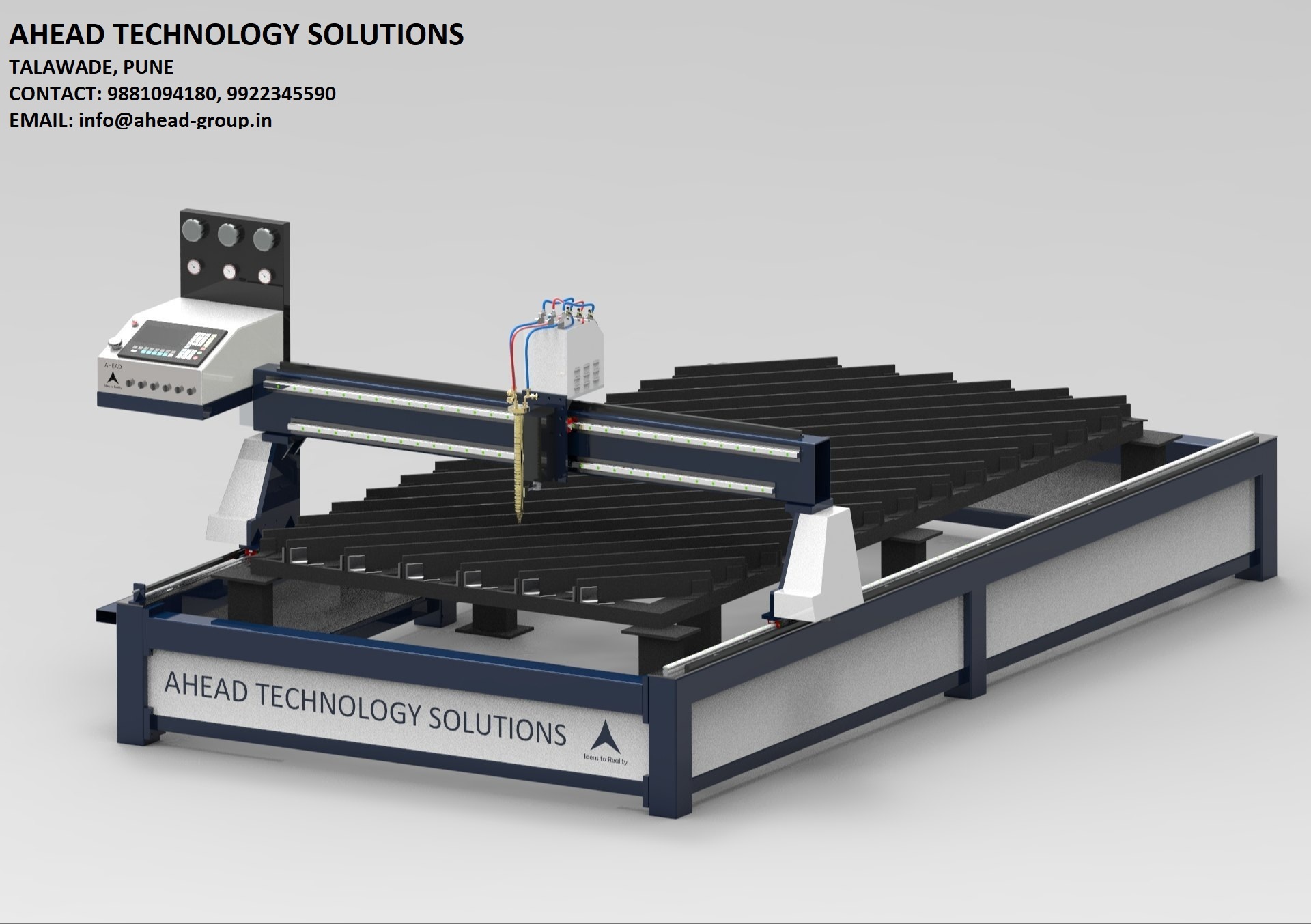

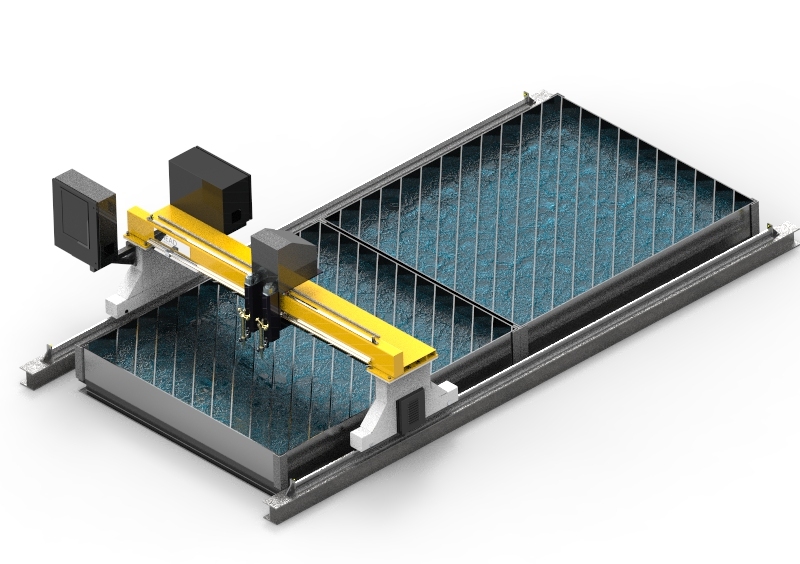

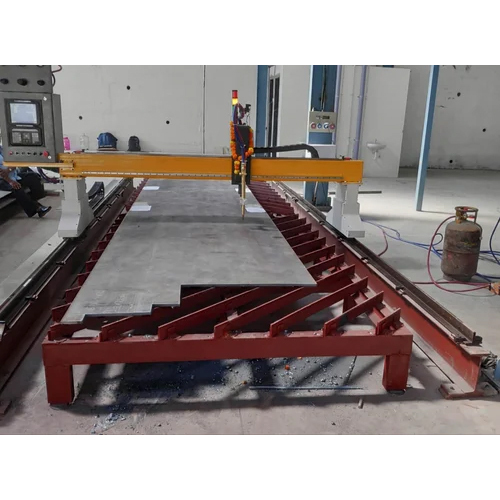

CNC Gas Cutting Machine

Product Details:

- Type Against Manufacturing Defect

- Material Steel

- Capacity 5000 Kg/day

- Computerized Yes

- Automatic Grade Automatic

- Cutting Speed 6000 mm/m

- Cutting Thickness 150 Millimeter (mm)

- Click to View more

X

CNC Gas Cutting Machine Price And Quantity

- 1 Unit

CNC Gas Cutting Machine Product Specifications

- Yes

- 6000 mm/m

- Full Automatic

- Yellow

- Steel

- Against Manufacturing Defect

- Automatic

- Electric

- 14000 x 4000 x 1800 Millimeter (mm)

- Air Cooling

- 12 Months

- 800 Kilograms (kg)

- 5000 Kg/day

- 150 Millimeter (mm)

CNC Gas Cutting Machine Trade Information

- Nhava Sheva

- Paypal

- 120 Unit Per Year

- 4 Week

- Yes

- If order is confirmed we will reimburse the sample cost

- Asia South America Middle East Africa

- Central India

Product Description

gas cutting machine is a precision tool used for cutting metal sheets and plates It operates based on computerized instructions allowing for accurate and efficient cutting

The process is often referred to asoxyfuel cutting where oxygen interacts with the metal resulting in iron oxide

CNC gas cutting machines can handle various grades of carbon steel

How Does It Work

The machine uses a combination ofoxygenand afuel gassuch as acetylene or propane to create a hightemperature flame

The flame heats the metal to its ignition point and the oxygen stream blows away the molten metal leaving a clean cut

The CNC system precisely controls the movement of the cutting torch along predefined paths ensuring accurate shapes and dimensions

Advantages of CNC Gas Cutting Machines

Precision CNC machines offer high precision and repeatability resulting in accurate cuts

Automation The automated process reduces manual labor and increases productivity

Versatility These machines can cut various shapes and sizes making them suitable for different applications

CostEffective CNC gas cutting is costeffective compared to laser or plasma cutting methods

Applications

Metal Fabrication CNC gas cutting machines are commonly used in metal fabrication workshops to create parts for machinery structures and vehicles

Shipbuilding Shipyards use CNC gas cutting for hull plates frames and other components

Construction Steel beams columns and other structural elements are cut using these machines

Automotive Industry CNC gas cutting is essential for manufacturing car frames and chassis

Enter Buying Requirement Details

Other Products in 'Plasma Cutting Machine' category

|

AHEAD TECHNOLOGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS